In Person

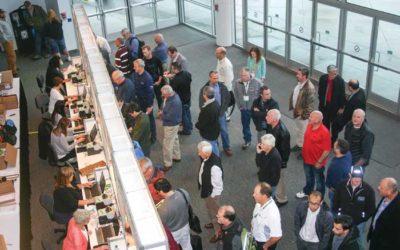

PORTLAND, Oregon – More than 110 wood producer companies, representing hundreds of mill operations, sent personnel to the Timber Processing & Energy Expo held September 28-30 at the Portland Exposition Center. More than 1,200 (non-exhibitor) attendees from 35 states and 15 countries registered for the event. They combed the aisles of 170 exhibitor companies, who were represented by more than 900 exhibitor personnel.

The event has always been heavier to the Northwest wood products industry, and was so again, especially since companies in other regions of the country might have been hesitant to send personnel coming out of the pandemic. “But there was still an okay showing from sawmillers in the Southern U.S.,” comments Rich Donnell, show director.

Donnell adds that the total attendee numbers were on par with the 2018 event, which isn’t bad considering the pandemic (which canceled the 2020 event) and taking into account some contraction of the Northwest wood products industry in the past four years.

“Four years ago was a long time ago, with all that has transpired since then,” Donnell adds. “Walking throughout the show floor I sensed a measure of relief and enthusiasm from people who were happy to be out and returning to this event. TP&EE provided a gauge of normalcy.”

Though lumber markets, housing starts and interest rates weren’t the be-all end-all they were in 2021, many sawmillers had equipment upgrades on their mind. A survey of a sampling of the exhibitors conducted following the event revealed that more than 80% of exhibitors either had confirmed an order or indicated it was possible that discussions at TP&EE will contribute toward receiving an order. Many exhibitors also reported they had accumulated some good leads for down the road.

Nearly 94% of the exhibitors surveyed said they were satisfied or very satisfied with the quality of attendees, and more than 70% were pleased with total attendance in general.

“We will continue to survey the exhibitors but the ‘early returns’ look good,” Donnell said. “We’re very appreciative of their commitment to the event, a commitment that really lasted four years since the last show. We all know everybody can conduct business virtually, but our industry still has a sense of community that lends itself to socializing and doing business in person.”

Many wood producer companies showed their support for the show and the industry by sending lots of personnel. For example, Sierra Pacific Industries registered more than 100 and Hampton Lumber registered more than 150.

The Portland show has always been for mill personnel as well as for executive management, Donnell adds. “I just think it’s totally cool looking down the aisles and seeing somebody from nearly every conceivable position in a sawmill operation wearing the logo of their company on the back of their jacket. I know they may not be the ultimate decisionmaker, but what they have to say trickles heavily back to the decision-makers. And I thought they were totally engaged with most of the exhibitors.”

TP&EE formed alliances with several “Preferred Partners” for assistance in promoting the event. One of those was the Western Wood Products Assn., and it was obvious WWPA’s participation proved beneficial in bringing in sawmillers. “There are several associations throughout the country that we need to tie into TP&EE and I believe the example of WWPA puts us on the right path in that regard,” Donnell says, adding several wood industry publications also did a great job in promoting TP&EE.

Highlight of the first day was the presentation by Timber Processing magazine of its 34th annual Person of the Year award to Eric Schooler, recently retired CEO of Collins and well known Northwest lumberman. (See page 26 for full coverage of the presentation.)

TP&EE also hosted two one-day conferences. One was entitled “Sawmill Productivity & Efficiency,” which featured 10 speakers addressing current and future sawmilling.

“During the past 15 years many changes have taken place in lumber manufacturing methods. These have been in response to worldwide changes in the character and value of the raw material, rising costs, shifting human resources, and new conversion concepts,” commented Chris Brown, VP at Mid-South Engineering, during his talk “Simplicity Is the Ultimate Sophistication.”

Brown pointed to the evolution of sawmill size: 1977, 54.66MMBF; 1997, 133.04MMBF; 2007, 180.42MMBF; 2015 to present, average greenfield production per mill, 285MMBF.

Current challenges include labor, lead times and capital costs, and lack of simplicity, he said, pointing to control systems and design complexity. Though the human resource is less content to do manual labor, he is more mobile and better educated, Brown added.

Terry Brown, longtime director of the Lumber Quality Institute, spoke on the evolvement of quality control leadership, and looking to the future said AI technologies and system-wide integration will change the role of QC to monitoring systems and calibrating primarily, which will leave more time for drying and planer evaluation and other areas, along with some continued role to watch the process and diagnose problems.

Brown said you can have the latest, greatest greenfield sawmill but without management commitment to excellence, listening to their people, and committing to world class maintenance and support, significant dollars are lost.

He injected a quote from legendary lumberman Buford Price: “It is management’s responsibility to provide a process that works. It is the employee’s responsibility to cause that process to perform.”

Vaughn Emmerson, engineering manager with Sierra Pacific Industries, spoke on minimizing downtime during shutdown and equipment installation. “Get into the details,” Emmerson said. “Break down each process into tasks and jobs.”

He stressed organization, including staging in the order that equipment will be used and keeping a map of equipment staging with numbers and colors identification.

Emmerson recommended building and testing offline as much as possible. “It helps get the bulk of the problems and hang ups out of the way, and gives proper time to trouble shoot,” he said.

Training the crew before installation is crucial as well, for sake of familiarity with equipment: post drawings in the breakroom, have operators visit another facility and even operate equipment at another facility. And have mill electricians wire up new equipment with contractors.

Mike Zojonc, plant manager at Gilchrist Forest Products in Oregon, and a longtime sawmiller, spoke on what makes a successful project. He should know, having led many project efforts at several companies and currently leading a massive upgrade program at Neiman-Gilchrist, including at last count 43 projects.

Zojonc first emphasized project safety. “One injury can ruin an otherwise good project,” he said, and pointed to the importance of developing a safety plan, daily safety meetings, daily safety inspections.

As to a project, he said it’s important to determine what it is really trying to accomplish— whether production increase, grade recovery, altering product mix, replacing older equipment, reducing staffing, etc.

He asked several questions: What’s the impact on upstream and downstream? What’s the seasonal weather factor? What about the spare parts supply chain? Can surge capacity be added? Can you get additional employees?

Zojonc said planning cannot be over-done or over-emphasized. Include an acceptance test in the contract, and know how you are going to measure success, he said. A post project meeting should address what went right and what could have been better.

Other speakers included Phil Johnson of Johnson Consulting, who addressed the use of used equipment in sawmill construction and upgrades; Sam Pope, Western Sales Manager, USNR, speaking on the well-planned project and techniques to deliver ROI; Kevin Collins, director at Strategic Energy Group, on maximizing productivity, operating efficiency and energy applications; Simon Potvin, president of the Wood Processing Div., BID Group, on his company’s emphasis on Artificial Intelligence and robotics, and the importance of overcoming the “knowledge gap” brought on by new technologies and systems versus inexperienced labor and BID’s establishment of a Global Learning Center; Norvin Laudon, director of MiCROTEC, on absolute SMART streamlining of the sawmill process based on incoming log scanning values and real-time machinery adaptabililty; and Justin Price, Co-CEO, Evergreen Engineering, on the implementation of Digital-Twin interoperability and advance technology adoption toward future-proofing your operations.

A second conference was entitled “From Forest to Frame: Mass Timber Developments.” Allan Czinger, senior account manager, USNR, spoke on “Optimizing Sawmills for Mass Timber Production” and noted that even if the projections for growth is half of what is forecasted, CLT and mass timber will consume a volume of lumber that is too big to be ignored, and that sawmills will need to optimize their overall manufacturing process to take advantage.

And there’s plenty of potential, Czinger said, citing CLT manufacturing wood fiber residual at 20-30% compared to 30-40% dimension lumber manufacturing, and based on optimization study results of multiple log sizes, CLT products show a 6% average recovery increase.

Other speakers included Evan Schmidt, outreach and education manager at TallWood Design Institute, who moderated a discussion involving several experts on tracking and transparency in the forest supply chain; Iain Macdonald, director of TallWood, on the Oregon Mass Timber Coalition and connecting Oregon’s forest to mass timber manufacturing and affordable modular housing; Janelle Leafblad, senior director, WoodWorks, on the growing market demand for wood products; Russ Vaagen, CEO of Vaagen Timbers, on his company’s early role in mass timber development and mass timber now moving into mainstream construction with a solid environmental message supporting it; and Derek Ratchford, CEO of SmartLam, on mass timber growth in the U.S. South, including the company’s recent announcement that it will build a glulam plant adjacent its CLT plant in Dothan, Ala., and also expand production of CLT in Dothan and at its CLT facility in Columbia Falls, Mont.

The next TP&EE is scheduled for September 25-27, 2024.

Latest News

Saw Filing, Scanning, Profiling, Controls Highlight Lumber Manufacturing Workshop At TP&EE

Fifteen presentations make up the Lumber Manufacturing Workshop, which will be held Thursday, September 29, during the Timber Processing & Energy Expo at the Portland Exposition Center in Portland, Ore. TP&EE will be held September 28-30. TP&EE is produced...

Cross-Laminated Timber, New Panel Production Technologies Highlight Plywood And EWP Workshop

A new engineered wood product called cross-laminated timber, new plywood mills and new technologies will be among the subjects addressed at the Plywood and Engineered Wood Products Manufacturing Workshop scheduled for Wednesday, September 28, during the Timber...

TP&EE Announces First Round Of Presentations For Lumber Manufacturing Workshop

Lumber manufacturing machinery legend Ron McGehee will deliver one of the technical presentations as part of the Lumber Manufacturing Workshop scheduled for Thursday, September 29, during the Timber Processing & Energy Expo. TP&EE will be held September 28-30...

2016 TP&EE Organizers Face Good Problem

It’s a sell-out! Well, sort of, as organizers of the third Timber Processing & Energy Expo (TP&EE) are still considering whether to add exhibitor space for the event to be held September 28-30 at the Portland Exposition Center in Portland, Ore. Nearly 190...

2016 Timber Processing & Energy Expo Is Bigger And Better

Dear Exhibitor, I am very pleased as a representative of Hatton-Brown Expositions to once again serve as your Exhibits & Sponsorships Sales Director for the Timber Processing and Energy Expo to be held September 28-30, 2016 at the Portland Exposition Center in...